Steel forgings play a pivotal role in the manufacturing of wind turbines, ensuring the structural integrity and durability of critical components. The global wind turbine forging market, valued at USD 7.90 billion in 2023, is projected to grow at a CAGR of 7.5%, reaching nearly USD 13.10 billion by 2030. This growth reflects the increasing demand for renewable energy solutions and the need for high-volume production to meet ambitious clean energy targets. Offshore wind farms, expanding rapidly across Europe, the United States, and Asia, further highlight the necessity for robust forged materials capable of withstanding harsh environmental conditions. This Steel Forgings Case Study explores how innovative manufacturing approaches address these challenges.

Key Takeaways

- Steel forgings are important for wind turbines. They add strength and last long in tough conditions.

- The need for wind turbine parts is growing fast. This is because more people want clean energy.

- New ways of making parts can make turbines stronger and last longer.

- Making more parts quickly helps companies meet the rising demand.

- Using eco-friendly methods in forging cuts waste and helps the planet.

- Custom-made parts fit different turbine designs and work better.

- Smart tools like robots and digital models save time and money in production.

- Working with skilled suppliers helps companies use the best technology for great results.

Challenges in Wind Turbine Manufacturing

Growing Demand for Renewable Energy Solutions

The global push for renewable energy has significantly increased the demand for wind turbines. State mandates and federal incentives, such as the production tax credit (PTC), have encouraged the adoption of wind energy by reducing costs for investors. This has led to a surge in turbine manufacturing, with companies timing their production to maximize tax benefits. The wind turbine forging market, for instance, is projected to grow from $10.93 billion in 2023 to $16.5 billion by 2032, reflecting a compound annual growth rate (CAGR) of 4.68%. This growth underscores the importance of scaling production to meet sustainability goals.

However, the industry faces challenges due to high market concentration. A few dominant players control the market, creating barriers for new entrants. These barriers include substantial capital requirements, legal hurdles, and the need for specialized knowledge. Despite these obstacles, advancements in forging technology, as highlighted in this Steel Forgings Case Study, offer solutions to meet the growing demand efficiently.

Material Durability and Environmental Resistance

Wind turbines operate in harsh environments, from offshore locations to high-altitude terrains. Components must withstand extreme conditions, including corrosion, fatigue, and ice accumulation. Research has identified several durability challenges. For example, stress corrosion cracking in slip-ring connectors and corrosion-fatigue in steel welded joints can compromise turbine reliability. Superhydrophobic coatings have emerged as a promising solution to mitigate ice buildup, enhancing blade performance and reducing downtime.

Environmental resistance also poses significant challenges. The manufacturing of turbine blades involves composite materials like fiberglass and carbon fiber, which are durable but energy-intensive to produce. This high energy consumption conflicts with the sustainability objectives of renewable energy. Innovations in material science, such as recyclable or bio-based composites, are essential for addressing these issues while maintaining performance standards.

Cost and Efficiency Challenges in Production

The production of wind turbines is both labor and capital-intensive. High energy consumption during manufacturing, particularly in curing and molding processes, increases costs and carbon emissions. Additionally, the use of composite materials generates substantial physical waste, much of which is non-recyclable. Hazardous emissions, including volatile organic compounds, further complicate environmental compliance and worker safety.

Efforts to improve efficiency focus on advanced manufacturing techniques and material innovations. For example, recyclable composites and bio-based materials can reduce waste and environmental impact. These advancements not only lower production costs but also align with global sustainability initiatives. By adopting such practices, manufacturers can enhance their competitive advantage while addressing the industry’s pressing challenges.

Steel Forgings Case Study: Addressing Industry Challenges

Strength and Longevity of Steel Forgings

Steel forgings are renowned for their exceptional strength and durability, making them indispensable in wind turbine manufacturing. These components endure extreme stress and environmental conditions, ensuring the reliability of turbines over their operational lifespan. Studies have consistently highlighted the superior performance of steel forgings in addressing corrosion, wear, and fatigue. The following table summarizes key findings from recent engineering research:

| Study | Focus | Findings |

|---|---|---|

| Menghani and Nandedwalie | Corrosion and wear in wind turbines | Discusses issues and prevention methods for longevity of components. |

| Zhang et al. | Corrosion endurance in bolts | Developed a method to predict corrosion endurance in high-strength bolts. |

| Piao et al. (2025) | Correlation between corrosion and fatigue life | Investigates how corrosion weakens fasteners, impacting their longevity. |

These insights underscore the critical role of steel forgings in enhancing the lifespan of wind turbine components. By addressing common durability challenges, manufacturers can reduce maintenance costs and improve turbine reliability.

Scalability for High-Volume Manufacturing

The growing demand for renewable energy has necessitated scalable manufacturing solutions. Steel forgings offer a unique advantage in this regard. Advanced forging techniques, such as free-die forging, enable the production of large, complex components with high precision. Rongli Forging Co., Ltd., for instance, leverages state-of-the-art equipment to manufacture products weighing up to 80 tons. This capability ensures fast lead times and consistent quality, even for high-volume orders.

Scalability also extends to customization. Manufacturers can tailor forged components to meet specific design requirements, ensuring compatibility with various turbine models. This flexibility, combined with the ability to produce at scale, positions steel forgings as a cornerstone of efficient wind turbine production.

Cost-Effectiveness and Competitive Advantage

Steel forgings provide a cost-effective solution for wind turbine manufacturers. The robust growth of the wind turbine forging market reflects their economic viability. The following table highlights key market trends:

| Aspect | Details |

|---|---|

| Market Growth | Robust growth driven by renewable energy shift |

| Market Size (Offshore Segment) | Estimated at $15 billion |

| Projected CAGR | 8% from 2024 to 2030 |

| Future Market Value | Estimated $35 billion by 2030 |

| Key Trends | Megawatt-scale turbines, offshore expansion, lightweighting, sustainability initiatives, increased R&D investment |

Additional data reveals that the wind turbine forging market exceeded USD 7.7 billion in 2022 and is expected to grow at a CAGR of 7.1% from 2023 to 2032. The rising demand for flanges, used in connecting specialty products, further underscores the economic benefits of steel forgings. By adopting these components, manufacturers can achieve significant cost savings while maintaining high performance standards.

Steel forgings not only reduce production costs but also enhance operational efficiency. Their durability minimizes downtime, while their scalability supports large-scale projects. These advantages provide a competitive edge in the rapidly evolving renewable energy sector.

Case Study Details

Project Background

Client Profile and Industry Context

The client, a leading wind turbine manufacturer, operates in a highly competitive renewable energy sector. With a focus on offshore wind farms, the company sought to enhance the durability and scalability of its turbine components. The industry demands robust materials capable of withstanding extreme environmental conditions, including high winds, saltwater corrosion, and temperature fluctuations. The client’s commitment to sustainability and efficiency aligned with the growing global emphasis on renewable energy solutions.

Objectives and Goals of the Project

The primary objective of the project was to develop high-quality steel forgings that could meet the rigorous demands of wind turbine manufacturing. Specific goals included:

- Enhancing the durability and lifespan of turbine components.

- Reducing production costs through advanced manufacturing techniques.

- Scaling production to meet increasing market demand without compromising quality.

- Aligning with sustainability initiatives by minimizing waste and energy consumption.

Methodology and Approach

Engineering and Design Innovations

The project employed cutting-edge engineering practices to address the challenges of wind turbine manufacturing. Key innovations included:

- Conducting comprehensive analyses to understand the differential impacts of the project on various stakeholders.

- Gathering user input through participatory research, surveys, and objective measures to ensure inclusive and effective design.

- Evaluating existing products and processes to identify areas for improvement and implement targeted solutions.

These strategies ensured that the design process was both data-driven and user-focused, resulting in components that met the highest standards of performance and reliability.

Advanced Manufacturing Techniques

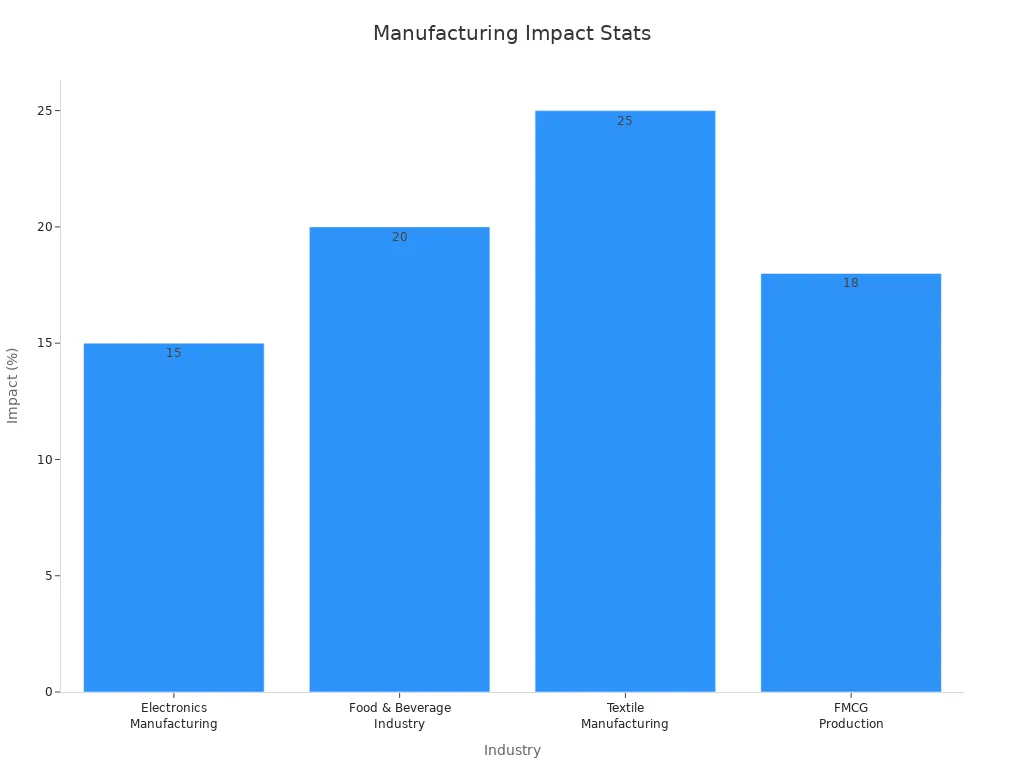

The manufacturing process leveraged state-of-the-art techniques to achieve precision and efficiency. The following table highlights the effectiveness of these methods across various industries:

| Industry | Method Used | Outcome Description | Result Impact |

|---|---|---|---|

| Automotive Production | PCA | Streamlined quality control by reducing variables, identifying key defect factors. | Cost savings through targeted improvements. |

| Electronics Manufacturing | CFA | Validated environmental impacts on production yield, leading to reduced scrap rates. | 15% reduction in scrap rates. |

| Food & Beverage Industry | Factor Score Regression | Predicted machine failures, reducing unplanned downtime. | 20% reduction in downtime. |

| Textile Manufacturing | EFA | Identified factors affecting production speed and quality, leading to efficiency gains. | 25% improvement in efficiency. |

| FMCG Production | SEM | Quantified interactions affecting production bottlenecks, improving throughput. | 18% increase in throughput. |

These advanced techniques enabled the production of steel forgings with exceptional precision, ensuring consistent quality and reduced waste.

Results and Achievements

Enhanced Component Durability

The project successfully improved the durability of wind turbine components. The use of high-quality steel forgings minimized issues such as corrosion, wear, and fatigue, significantly extending the operational lifespan of turbines. This advancement reduced maintenance requirements and enhanced overall reliability.

Cost Reductions and Efficiency Gains

By adopting innovative manufacturing techniques, the project achieved substantial cost savings. Streamlined processes and reduced material waste contributed to lower production costs. Additionally, the improved efficiency of the manufacturing process aligned with the client’s sustainability goals, further enhancing their competitive advantage.

Improved Production Scalability

The scalability of the manufacturing process allowed the client to meet increasing market demand effectively. The ability to produce large, complex components with high precision ensured that the client could fulfill high-volume orders without compromising quality. This capability positioned the client as a leader in the renewable energy sector, ready to support the global transition to sustainable energy solutions.

Analysis and Broader Implications

Comparison with Industry Standards

Benchmarking plays a vital role in evaluating the effectiveness of steel forgings in wind turbine manufacturing. By comparing the project’s outcomes with established industry standards, manufacturers can identify areas of excellence and opportunities for improvement. The following table highlights various benchmarking types and their applications:

| Benchmarking Type | Data Requirements | Example |

|---|---|---|

| Strategic Benchmarking | Strategic plans, industry leader data, benchmarking frameworks, expert insights | Analyzing industry leader case studies to improve strategic plans. |

| Functional Benchmarking | Detailed metrics on current processes, industry standards, analytical tools, expert consultations | HR department comparing recruitment metrics to industry standards. |

| Internal Benchmarking | Detailed internal data, benchmarking tools, communication platforms | Retail chain comparing sales performance across store locations. |

| External Benchmarking | Comparative data, detailed internal data, benchmarking tools and resources | Healthcare provider comparing patient satisfaction scores with leading hospitals. |

| Competitive Benchmarking | Competitor data access, internal data collection, benchmarking tools, networking data | E-commerce company comparing brand awareness KPIs with competitors. |

| Best-in-Class Benchmarking | Best-in-class data, internal data collection | Marketing team benchmarking KPIs against top-performing agencies. |

Steel forgings, as demonstrated in this case study, align closely with best-in-class benchmarks by delivering exceptional durability, scalability, and cost-effectiveness. These attributes position them as a superior choice compared to alternative materials, ensuring compliance with industry standards while driving innovation.

Impact on Wind Turbine Performance and Lifespan

The adoption of high-quality steel forgings significantly enhances wind turbine performance and extends their operational lifespan. Forged components exhibit superior resistance to corrosion, fatigue, and wear, which are critical factors in harsh environments such as offshore wind farms. This durability reduces maintenance requirements and minimizes downtime, ensuring consistent energy production.

Moreover, the precision and strength of forged components contribute to the structural integrity of turbines. This reliability supports the development of larger, more powerful turbines capable of generating higher energy outputs. By addressing common performance challenges, steel forgings enable manufacturers to meet the growing demand for renewable energy while maintaining high operational standards.

Implications for the Renewable Energy Sector

The widespread adoption of steel forgings has far-reaching implications for the renewable energy sector. The market is projected to grow at a compound annual growth rate (CAGR) of 5% to 7% between 2025 and 2033, driven by technological advancements and sustainable practices. Key trends include:

- Increased demand for wind energy due to global carbon reduction commitments.

- Growth in offshore wind farms requiring specialized forged components.

- Integration of energy storage solutions to enhance grid stability.

Innovative approaches, such as injecting hydrogen or biomass into blast furnaces, further reduce fossil fuel reliance in steel production. These advancements align with the sector’s sustainability goals, promoting near-zero emissions and reducing environmental impact.

Steel forgings not only support the expansion of renewable energy infrastructure but also drive economic growth through job creation and technological innovation. By investing in advanced forging techniques, manufacturers can contribute to a cleaner, more sustainable future while maintaining a competitive edge in the global market.

Future Trends in Steel Forgings for Renewable Energy

Advancements in Forging Technology

The forging industry is undergoing a transformation driven by technological advancements. Modern forging techniques, such as precision forging and free-die forging, are enabling manufacturers to produce components with unparalleled accuracy and consistency. These methods reduce material waste and improve the mechanical properties of forged parts, making them ideal for wind turbine applications.

Automation and robotics are also playing a pivotal role in enhancing production efficiency. Automated systems streamline repetitive tasks, ensuring consistent quality while reducing labor costs. Additionally, the integration of artificial intelligence (AI) and machine learning allows manufacturers to predict equipment maintenance needs, minimizing downtime and optimizing production schedules.

Digital twin technology is another innovation shaping the future of steel forgings. By creating virtual replicas of forged components, manufacturers can simulate performance under various conditions. This approach not only improves design accuracy but also reduces the time required for prototyping and testing. These advancements position steel forgings as a cornerstone of next-generation renewable energy infrastructure.

Sustainable Manufacturing Practices

Sustainability is becoming a central focus in the steel forging industry. Manufacturers are adopting eco-friendly practices to reduce their environmental footprint while meeting the growing demand for renewable energy components. Key aspects of this evolution include:

- The development of high-performance steel alloys that meet industrial specifications sustainably.

- Increased adoption of recycling and reuse practices to minimize waste.

- The integration of renewable energy sources, such as solar and wind, into manufacturing processes.

The following table highlights the impact of sustainable practices on the steel forging industry:

| Aspect | Details |

|---|---|

| Technological Advancements | Significant influence on the growth trajectory of sustainable practices in steel forgings. |

| Adoption of Sustainable Practices | Increasing adoption noted as a key factor in the evolution of manufacturing processes. |

| Development of Steel Alloys | High-performance steel alloys are being developed to meet industrial specifications sustainably. |

Steel production contributes significantly to emissions across various sectors, including construction, automotive, and renewable energy. By adopting sustainable practices, manufacturers can address these challenges while aligning with global environmental goals. These efforts not only enhance the industry’s reputation but also create opportunities for innovation and growth.

Customization and Innovation Opportunities

The demand for customized solutions in renewable energy is driving innovation in steel forgings. Manufacturers are developing specialized components tailored to the unique requirements of offshore wind farms, energy storage systems, and next-generation turbines. These innovations enhance the performance and reliability of renewable energy infrastructure.

The following table outlines emerging opportunities in steel forgings:

| Opportunity/Innovation | Description |

|---|---|

| Offshore Wind Farms | Expansion due to higher energy output potential, requiring specialized forged components. |

| Energy Storage Solutions | Integration with wind farms enhances grid stability, creating demand for forged components. |

| Advanced Materials | Research into lighter and more durable materials for next-generation turbine components. |

| Sustainable Practices | Emphasis on recycling and reuse of components aligns with environmental goals. |

| Digital Twin Technology | Enhances operational efficiency, requiring forged components with monitoring capabilities. |

| Localized Forging Facilities | Reduces transportation costs and delays, creating regional growth opportunities. |

Localized forging facilities are emerging as a key trend, reducing transportation costs and ensuring timely delivery of components. This approach supports regional economic development while addressing supply chain challenges. Additionally, the use of advanced materials, such as lightweight alloys, is enabling the production of larger and more efficient turbines.

By embracing customization and innovation, the steel forging industry is well-positioned to meet the evolving needs of the renewable energy sector. These advancements not only enhance operational efficiency but also contribute to a more sustainable and resilient energy future.

The case study highlights the transformative impact of high-volume steel forgings on wind turbine manufacturing. Key findings include enhanced component durability, significant cost reductions, and improved scalability. These advancements enable manufacturers to meet growing renewable energy demands while maintaining operational efficiency.

Wind turbine manufacturers can learn the importance of integrating advanced forging techniques to address durability and environmental challenges. Prioritizing scalable and sustainable production processes ensures long-term success in a competitive market.

Adopting high-volume steel forgings offers a strategic advantage. Manufacturers should collaborate with experienced suppliers like Rongli Forging Co., Ltd. to leverage cutting-edge technology and achieve superior performance in turbine production.

Post time: Mar-26-2025