Introduction

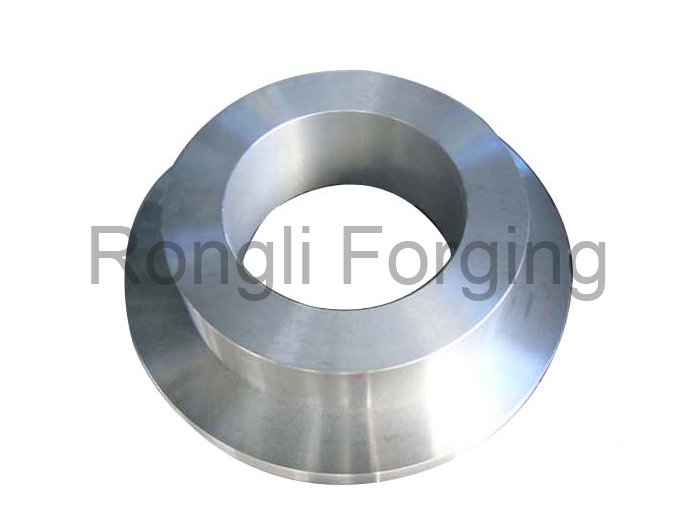

Rongli Forging Co., Limited is experienced in manufacturing hollow cylinders / tubes by open die forging and rough turning with our 2.5 m x 12 m (100” x 470”) lathe. We also provide closed-end cylinders, both with and without flanges, in various wall thicknesses and cylinder end configurations to accommodate our customers' requirements.

Material

We can accommodate customers’ requirements by applying variety kinds of carbon steel, alloy steel and stainless steel based on DIN, ASTM, ANSI, GB, BS, EN, JIS, and ISO.

| Forging method: | Open die forging / free forging |

| Mechanical properties: | According to customer requirement or standards. |

| Weight: | Up to 70 Tons of finished forging. 90 Tons for ingot |

| Delivery Status: | Heat treated and rough machined |

| Inspection: | Chemical analysis with spectrometer, Tensile test, Charpy test, Hardness Test, Metallurgy test, Ultrasonic test, Magnetic Particle test, Liquid Penetration test, Hydro test, Radiographic test are implementable. |

| Quality Assurance: | Per ISO9001-2008 |