China High Quality Steel Hot Forging Parts Factories – Forging flange – Rongli Forging Detail:

Introduction

Rongli Forging Co., Limited excels at providing forged & rough turned flanges per ASME, DIN, JIS and ISO standards. Carbon steel, alloy steel, and stainless steel can be applied according to customers’ needs. ASTM A105, A182, and A350 materials are commonly and frequently used in our forging shop. Our pipe flanges are exported to North America, Europe, Australia, South Africa, in industries of Oil & Gas, Mine & Mineral Processing.

Material

Carbon steel, low alloy steel and stainless steel as per ASTM A105, A182, and A350 or the equivalent ISO, JIS, BS and DIN designations. We can also do customized alloy as per customers’ requirement

| Forging method: | Open die forging / free forging |

|---|---|

| Mechanical properties: | According to customer requirement or standards. |

| Weight: | Up to 70 Tons of finished forging. 90 Tons for ingot |

| Delivery Status: | Heat treated and rough machined |

| Industries: | Oil & Gas, Mining & Mineral Processing, etc. |

| Inspection: | Chemical analysis with spectrometer, Tensile test, Charpy test, Hardness Test, Metallurgy test, Ultrasonic test, Magnetic Particle test, Liquid Penetration test, Hydro test, Radiographic test are implementable. |

| Quality Assurance: | Per ISO9001-2008 |

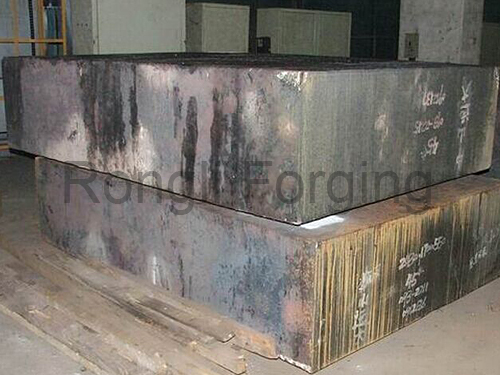

Product detail pictures:

Related Product Guide:

With reliable good quality system, great standing and perfect consumer support, the series of products and solutions produced by our organization are exported to quite a few countries and regions for China High Quality Steel Hot Forging Parts Factories – Forging flange – Rongli Forging, The product will supply to all over the world, such as: Myanmar, Victoria, Buenos Aires, "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We are willing to establish long business relationship with those who seek the high quality products and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!

-

China High Quality Customized Metal Forging Sup...

-

China High Quality Close Die Forging Supplier &...

-

China High Quality Forged Cylinder Die Block Ma...

-

China High Quality Forging Spindles Manufacture...

-

China High Quality Forged Cylinder Die Block Su...

-

China High Quality Carbon Steel Forged Parts Fa...