China High Quality Forgings Factory – Forging flange – Rongli Forging Detail:

Introduction

Rongli Forging Co., Limited excels at providing forged & rough turned flanges per ASME, DIN, JIS and ISO standards. Carbon steel, alloy steel, and stainless steel can be applied according to customers’ needs. ASTM A105, A182, and A350 materials are commonly and frequently used in our forging shop. Our pipe flanges are exported to North America, Europe, Australia, South Africa, in industries of Oil & Gas, Mine & Mineral Processing.

Material

Carbon steel, low alloy steel and stainless steel as per ASTM A105, A182, and A350 or the equivalent ISO, JIS, BS and DIN designations. We can also do customized alloy as per customers’ requirement

| Forging method: | Open die forging / free forging |

|---|---|

| Mechanical properties: | According to customer requirement or standards. |

| Weight: | Up to 70 Tons of finished forging. 90 Tons for ingot |

| Delivery Status: | Heat treated and rough machined |

| Industries: | Oil & Gas, Mining & Mineral Processing, etc. |

| Inspection: | Chemical analysis with spectrometer, Tensile test, Charpy test, Hardness Test, Metallurgy test, Ultrasonic test, Magnetic Particle test, Liquid Penetration test, Hydro test, Radiographic test are implementable. |

| Quality Assurance: | Per ISO9001-2008 |

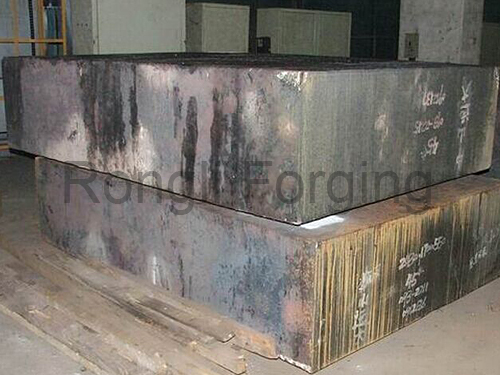

Product detail pictures:

Related Product Guide:

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for China High Quality Forgings Factory – Forging flange – Rongli Forging, The product will supply to all over the world, such as: Berlin, South Korea, Houston, Adhering to the principle of "Enterprising and Truth-Seeking, Preciseness and Unity", with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective products and meticulous after-sales service. We firmly believe that: we are outstanding as we are specialized.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

-

China High Quality Heavy Steel Forging Manufact...

-

China High Quality Steel Free Die Forging Suppl...

-

China High Quality Carbon Steel Forging Block S...

-

China High Quality HPGR High Pressure Grinding ...

-

China High Quality Free Die Forged Flange Facto...

-

China High Quality Heavy Steel Forgings Supplie...