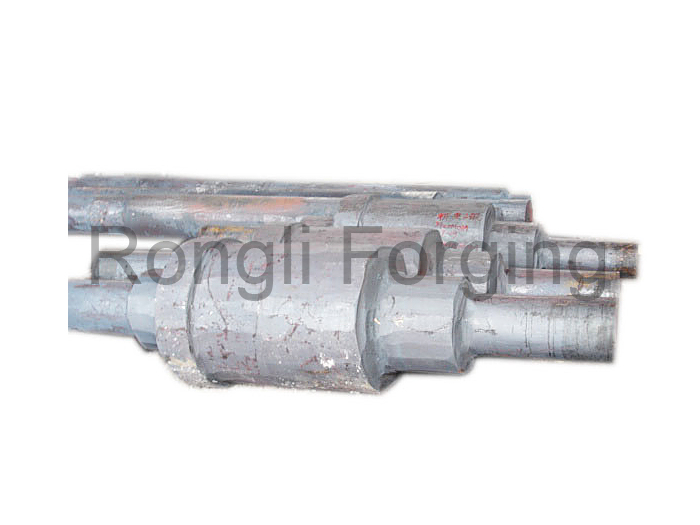

China High Quality Forging Steam Turbine Rotor Factory – Forging Steam Rotor Shaft – Rongli Forging Detail:

Introduction

Rongli Forging Co., Limited has a proven track history manufacturing Steam Turbine Shafts by open die forging and green machining. Our modern shops provide us capability to forge and rough turn shafts up to 20 meters (66 feet) in length and 70 tons (44,000 lbs.) in weight, in satisfying quality to ASTM A470 or the equivalent.

Material

Rongli Forging Co., Limited has a proven track history manufacturing Steam Turbine Shafts by open die forging and green machining. Our modern shops provide us capability to forge and rough turn shafts up to 20 meters (66 feet) in length and 70 tons (44,000 lbs.) in weight, in satisfying quality to ASTM A470 or the equivalent.

| Forging method: | Open die forging / free forging |

| Mechanical properties: | According to customer requirement or standards. |

| Weight: | Up to 70 Tons of finished forging. 90 Tons for ingot |

| Delivery Status: | Heat treated and rough machined |

| Inspection: | Chemical analysis with spectrometer, Tensile test, Charpy test, Hardness Test, Metallurgy test, Ultrasonic test, Magnetic Particle test, Liquid Penetration test, Hydro test, Radiographic test are implementable. |

| Quality Assurance: | Per ISO9001-2008 |

Product detail pictures:

Related Product Guide:

With this motto in mind, we've got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for China High Quality Forging Steam Turbine Rotor Factory – Forging Steam Rotor Shaft – Rongli Forging, The product will supply to all over the world, such as: Lithuania, Paraguay, Spain, The quality of our merchandise is equal to OEM's quality, because our core parts are the same with OEM supplier. The above items have passed professional certification, and we not only can produce OEM-standard items but we also accept Customized Merchandise order.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!